From large panels to harvested microwatts from a few photodiodes, solar power is increasingly prevalent in autonomously powered systems. With the worldwide evolution toward lower power operation using more “green” energy sources, emphasis on deploying solar power in a greater variety of environments has been on the rise.

In low-power solar systems, it is critical to assess whether there is sufficient sunlight at a given time to power the system. In some cases, this involves determining whether there is sufficient power to enable the microcontroller. In many ultra-low-power systems, the simple act of waking the microcontroller to make a voltage measurement might collapse the solar source or waste precious power from a reservoir capacitor.

One solution is to incorporate a simple analog op amp into the system. An ultra-low-power analog op amp can support “always-on” circuitry around the microcontroller and may be the simplest and best solution.

Ultra-Low-Power Op Amps

Figures 1 to 3 illustrate a few simple circuits using an ultra-low-power op amp in a continuous “always-on” measurement mode assessing the state of the solar cell. The technique hangs on using an op amp whose total power is as low as practical driven primarily by ultra-low supply voltage operation.

The circuit in Fig. 1 shows a photodiode in photovoltaic zero-bias mode. The short-circuit current is measured and converted to a voltage across resistor R1 while the feedback action of the op amp forces 0 V across D1. Zero-bias photovoltaic current is a convenient parameter that is generally well characterized and can be directly referenced to most photodiode manufacturer datasheets. Note that with the rail-to-rail input range of the analog op amp, in this case Touchstone Semiconductor’s TS1001 op amp, the photodiode may be connected directly to the positive supply voltage rail.

Figure 1 An ultra-low-power op amp can be a continuous, “always-on” measurement mode.

The circuit in Fig. 2 generates a simple positive-polarity output for a similar zero-bias-mode measurement. In this case, the op amp servos its output to sink sufficient current to support the zero bias condition for D1. This creates a voltage across resistor R1 at the negative supply voltage pin of the TS1001. Since this ultra-low-power op amp contributes less than 1 μA to this current, the current measured from D1 has minimal error.

Figure 2 An ultra-low-power op amp offers simple, positive polarity output to support a zero bias condition.

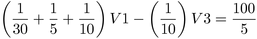

For a more comprehensive assessment, the circuit in Fig. 3 tests the solar source to see if it can handle the load. The circuit shown makes this assessment without burdening the microcontroller and risking collapse of the supply during measurement.

Figure 3 An ultra-low-power op-amp-based circuit assesses a PV solar-cell source.

Approximately once per 100 ms, the circuit disconnects the solar-cell power source from its reservoir capacitor and load, applying a test load (R1) and assessing the resulting voltage drop. If the voltage drops 25% or more, the result is latched into U2 and the power status is provided to the microcontroller.

This ultra-low power circuit draws less than 3 μA at 1V. Op amp U1 provides the timer function and controls transistor switches T1 and T2 to apply the test load while simultaneously disconnecting the load. Capacitor C1 temporarily holds the voltage to keep this circuitry and any standby loads powered. Op amp U2 serves as a comparator, tripping when the power source drops more than 25% (with 5% hysteresis). Transistor T3 latches the result, while transistor T4 resets the latch during each assessment period to ensure a fresh reading.

Such test loading is useful for determining the available power from a solar cell, since merely measuring the open circuit voltage generally does not provide an accurate assessment.

Assessing “Always-On” CircuitryGenerally, an ultra-low-power op amp, like Touchstone Semiconductor’s TS1001, is an excellent option for supporting “always-on” analog circuitry. For example, op amps that are guaranteed to operate under 1 V and consume less than 1 μA current may be configured as a filter and left continually on, so that a microcontroller making an ADC measurement does not have to stay powered on while the filter settles.

In conclusion, ultra-low-power op amps are useful in low-power solar systems to assess the available power from solar cells before a load is applied, and generally to support standby, “always-on” circuitry, while drawing negligible currents.

source :http://www.eeweb.com/blog/brett_fox/using-analog-components-to-manage-power-in-low-power-solar-systems5

23:32

23:32

Unknown

Unknown